| TILLIG Modellbahnen GmbH | Promenade 1 | 01855 SebnitzTel.: +49 (0)35971 903-0 | Fax: +49 (0)35971 903-19 | E-Mail: info@tillig.comCookie-Einstellungen |

|

TILLIG Modellbahnen GmbH

Promenade 1

01855 Sebnitz

Tel.: +49 (0) 3 59 71/903-0

Fax: +49 (0) 3 59 71/903-19

E-Mail: info@tillig.com

Company

Quality and precision in all regions ...

Precision, attention to detail and reliability. These are the outstanding features of our products. We do of course subject our work to the highest demands in all our manufacturing steps to achieve this goal.

Design:

Many years of experience of our designers, modern CAD systems and a constant search for

innovations: The „foundation stone” for a successful TILLIG model is laid here.

All TILLIG models emerge in the construction.

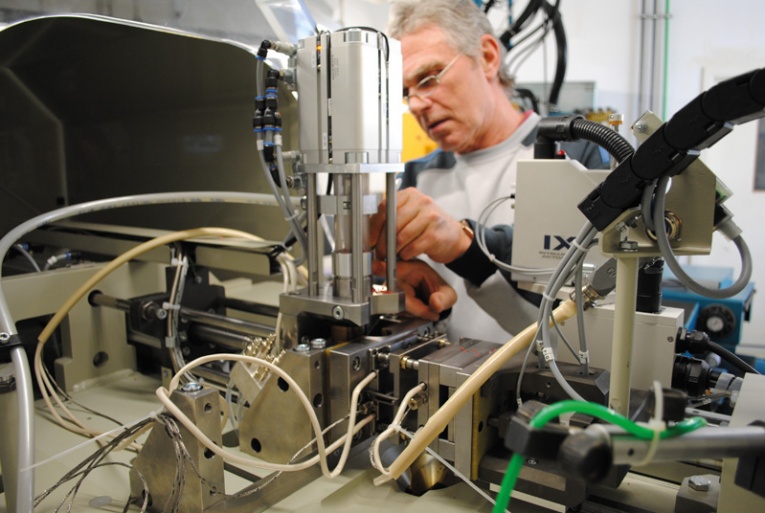

Tool construction:

High attention to detail, the finest engravings on the models, tolerances down to

a hundredth of millimeter. State of the art technology is available to our specialists in the tool

construction sector to this end.

Plastic injection moulding plant:

Automated injection moulding machines guarantee a highly productive output of injection moulded parts.

The ideal settings and constant monitoring of the injection moulding parameters (temperature, pressure,

the cooling period etc) is imperative to ensure the quality of the plastic parts.

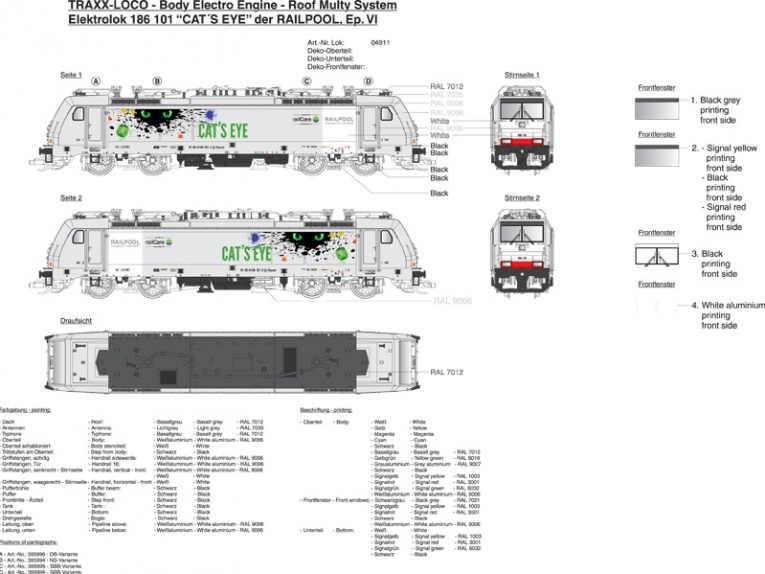

Pre-press:

The templates for the lacquering and printing on the PC are produced following the most

precise research of the decoration of the original..

Paintshop and printing shop:

The models are painted with a hand spray gun. Great experience is essential here to ensure

the paint is applied evenly. High definition printing of our models is made possible by pad printing,

often smallest inscriptions can only be read under a loupe.

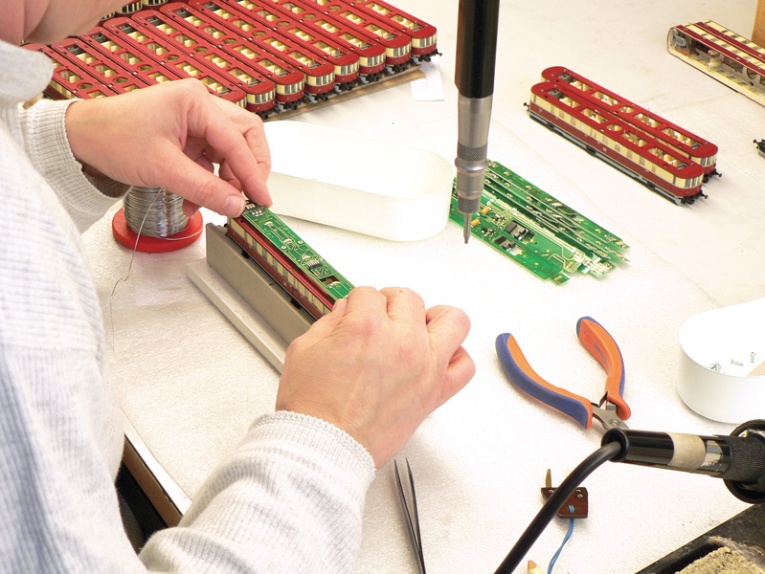

Final assembly:

Both the construction of the structure and the assembly of the models is performed almost

exclusively by hand. Patience and dexterity are called for here. Our assembly employees always master

this with a great deal of painstaking attention to detail.